|

FOR IMMEDIATE RELEASE

Molex Incorporated Announces Immediate Availability of the Copper Flex Assembly with HD&S PC Beam Interposer

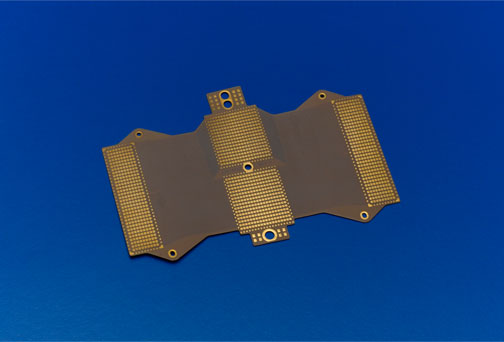

LISLE, Ill. � January 31, 2008 � With high-density, high-speed applications in mind, Molex Incorporated and Neoconix have partnered to deliver a flexible, copper-based high-density and speed (HD&S) interposer. The low-profile contact interface integrates Molex Copper Flex with Neoconix�s HD&S PC Beam interposer for flex-to-PCBA applications. Ideal for telecommunication, server, mass storage, medical imaging, automatic test equipment (ATEA) and military command and control center markets, Molex�s Copper Flex assembly with HS&S PC Beam interposer enables unparalleled design flexibility and true position accuracy.

�Molex and Neoconix have come together to develop a highly-reliable interface that allows differential signal speeds greater than 10 Gbps and single-ended speeds of 4 GHz and higher,� said Gary Manchester, director of marketing, Molex Incorporated, integrated products division. �With less than 3 percent cross talk in a pin-matrix configuration, the copper flex assembly with PCBeam interposer will provide consistent, high-speed data transmission with minimal interference.�

Molex�s Copper Flex assembly with PCBeam interposer includes the following additional features:

- Densities of 1.00mm (.039�) or less in a variety of pin-matrix configurations;

- Board-to-flex pin counts of 500 input/outputs or greater;

-

- Single-piece compression and tool-less hardware interfaces; as well as

- An impedance matched system that offers 100 Ohm differential and 50 Ohm single-ended options.

PCBeam interposers feature all-metal spring beams that are permanently embedded onto an FR-4 substrate in a high-density configuration. Photolithography and etch are used to define the contact elements, enabling unparalleled design flexibility and true-position accuracy. Typical configurations provide 0.152mm (.006�) of true electrical compliance (TEC) per side at 1.00mm (.039�) pitch to ensure high reliability. An innovative dual-beam option is also available to provide contact redundancy in high-reliability applications.

Copper Flex assemblies with PCBeam interposer are available in flexible cable lengths of 4 to 28 inches for complete design flexibility, and are offered in a variety of thicknesses and custom array of sizes and footprints.

# # #

|